Optimised Engineering Design 2016: Learning Zone Activities

In April 2016 GRM held our latest Optimised Engineering Design Event, delivering presentations from major OEMs in the Automotive, Medical and Rail industries, and allowing attendees to meet with our experienced engineers to discuss projects and processes. Below is more information on the demonstrations areas and activities that will be available throughout the day to assist with learning and understanding.

| Demonstration stands for products and key disciplines |

||

| CFD; Computational Fluid Dynamics |

|

Demonstrations of XFlow meshless, transient CFD simulation applications. |

| Composites |

|

Learn about our latest tools available for composite analysis, optimisation and manufacturing preperation through example applications. |

| Topology |

|

Through application examples understand the latest methods available in Genesis and TruForm. |

| Non Linear Analysis |  |

Discover the range of advanced simulation applications undertaken by GRM's consulting team. |

| Optimisation in Design |  |

Case studies of applications of optimisation embedded within the design process, demonstrating the best practises and benefits that can be achieved. |

| Research and University Projects |

||

| CLASS |

|

Composite Lightweight Automotive Suspension System - CLASS is a 24 month research project co-funded by Innovate UK, the UK's innovation agency via the Adapting Cutting Edge Technologies Call. The CLASS project has been led by Ford in partnership with GRM, Gestamp Chassis and WMG, University of Warwick. The project aims to overcome the technical, financial and environmental challenges of high volume production of a lightweight composite Tieblade-knuckle for a wheel suspension system. |

| ULTRAN |

|

With the support of Innovate UK, Jaguar Land Rover (JLR) are leading a 3 year collaborative research project titled ULTRAN (Ultra Lightweight Transmission and Driveline), with the aim of developing complimentary lightweight technologies in order to provide a step-change in powertrain weight. |

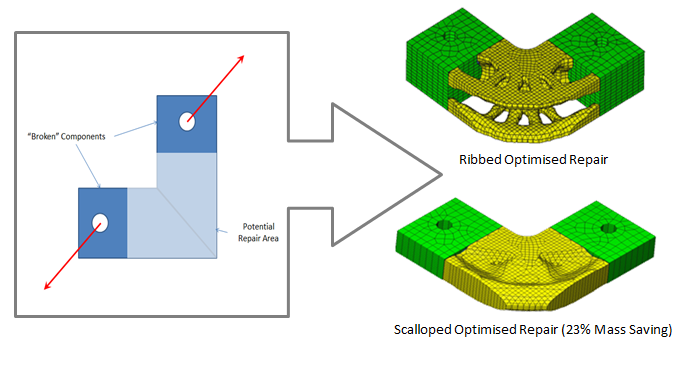

| PEEK |

|

A research project conducted with the University of Exeter's Centre for Additive Layer Manufacturing (CALM), investigating the potential to develop carbon reinforced PEEK composite repairs for aluminium components, utilizing solid topology optimisation strategies. |

| VARCITY |  |

A 36 month project which aims to investigate and develop design, simulation and manufacturing methods for composite BIW design, culminating in the production of a demonstration of affordable composites BIW architectures. |